Product (OEM&ODM)

Top class production share in domestic oven-range.

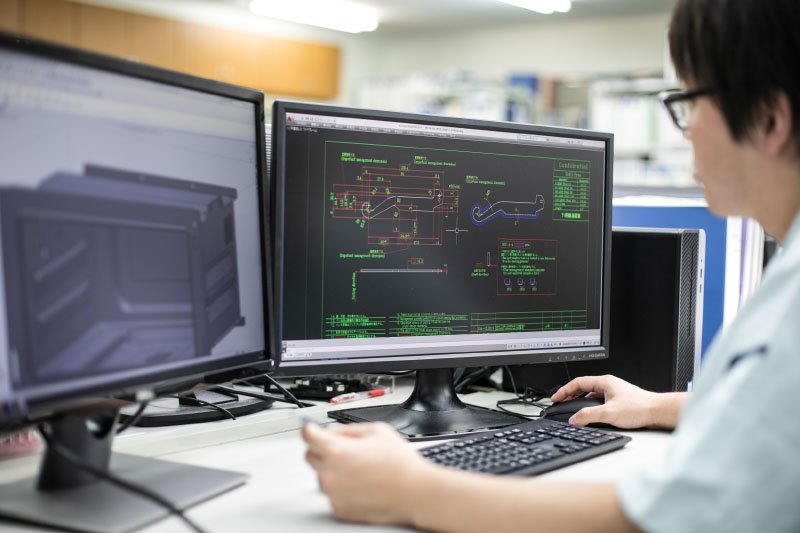

We provide services for development, such as building a joint development system or creating a product from scratch based on the product concept.

Based on the past 40 years of experience in developing home appliances, joint development and commercialization with customers, we can talk technically from the standpoint of the customer.

In a market with various needs, you can win trust with our flexible ideas and appropriate planning.

Capability of export to various countries.

●Overseas export destinations

North America

America, Canada

Europe

West Europe、Russia

Asia

China , Hong Kong, Taiwan, Korea

Planning / Mold / Mass production Full process support.

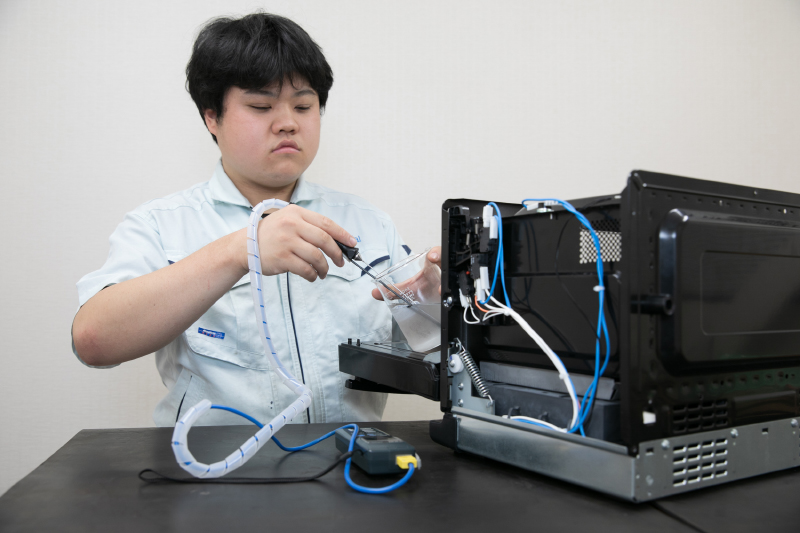

By cooperating with production factories, we respond to needs such as quick delivery and mass production with excellent supply capabilities.

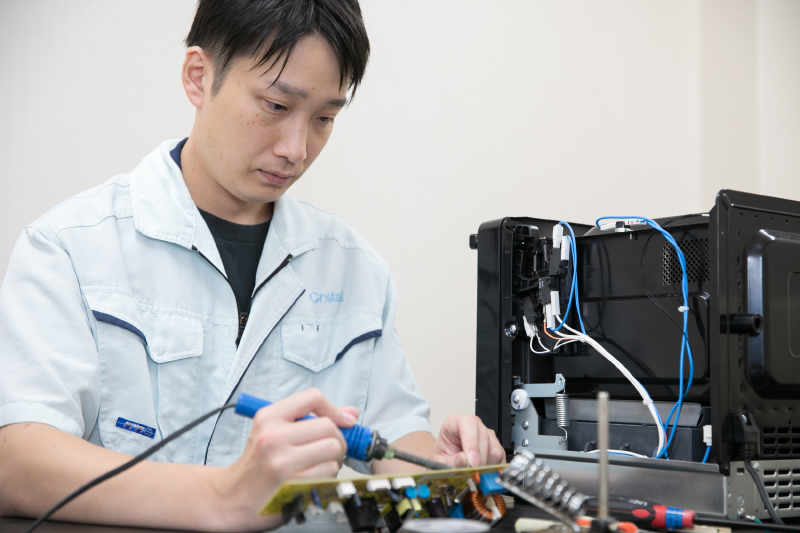

The factory makes thorough quality control on a daily basis, making the best use of its advanced technical capabilities with the motto of producing safe products.

We also provide technical guidance to local staff from our company and work on manufacturing products from a detailed perspective to meet the requests from our customers. For quality problems and issues, we will clearly identify the cause and improve the production process to make better products.

We aim to create products that achieve superior quality, reasonable prices, and satisfy all performance, quality, and cost through partnerships with customers.

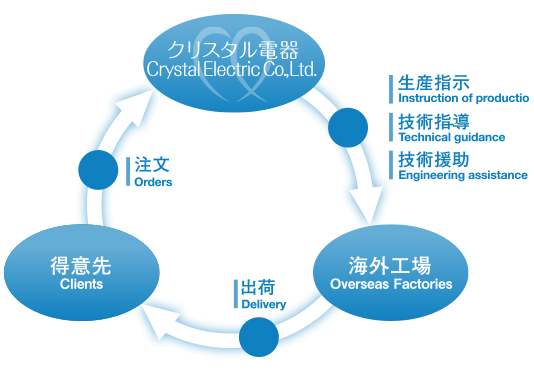

Flow of OEM & ODM development

We introduce all processes related to products from planning design to mold arrangement to mass production.

live_helpQ&A for OEM&ODM

ODM stands for “Original Design Manufacturer”, which means that our company designs and produces under the brand of the partner company. We also do joint development between OEM and ODM.

The factory works with Crystal Electric to produce and manage products that meet customer quality standards.。

Crystal electric and factories communicate closely and work together to enable high-level development, production, and quality control to meet customer requirements.